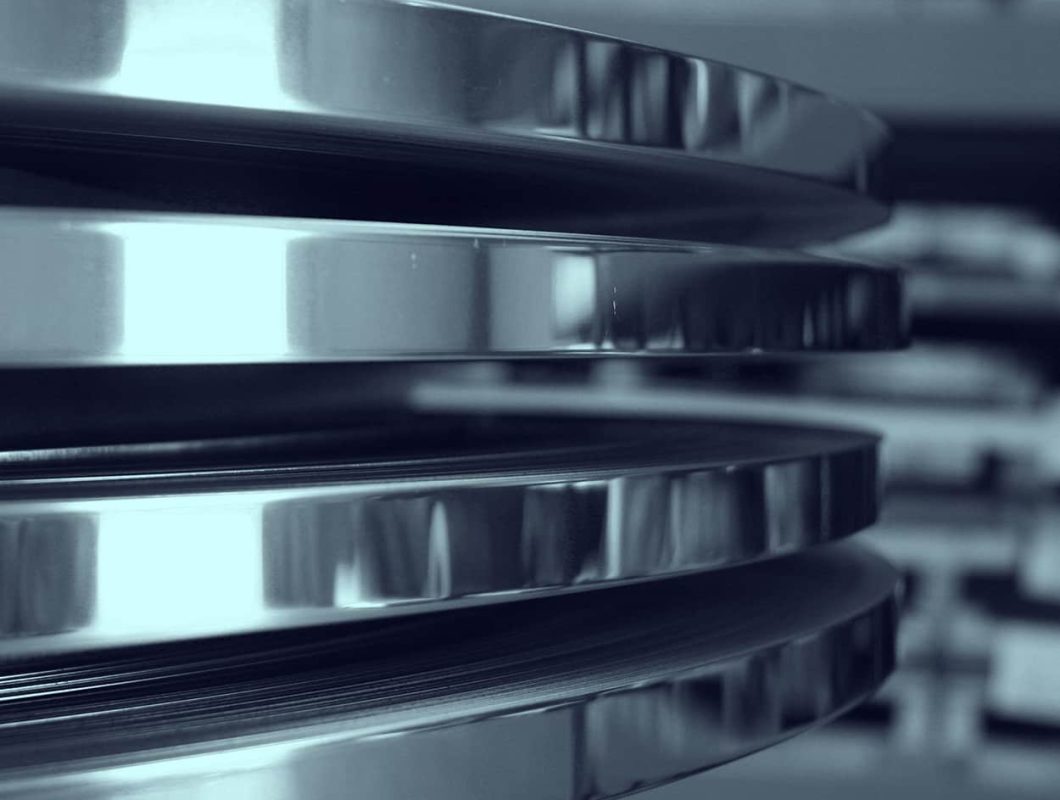

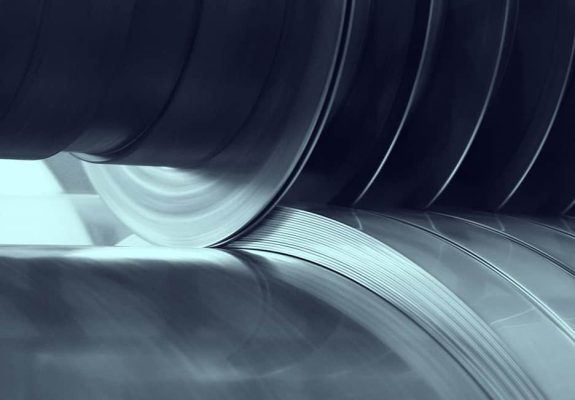

Produced from a range of Stainless Steel Austenitic and Martensitic grades (300 and 200 series), coils can be annealed and then cold-rolled under controlled conditions to achieve a consistent temper, improved flatness (less camber) excellent surface quality and enhanced mechanical properties.

Additionally, Ferritic grades 430 & 441 can be supplied Temper Rolled.

Temper Rolling of Stainless-Steel Cold Rolled coils delivers an additional reduction, which can significantly increase the Tensile Strength and Hardness, whilst reducing Ductility and coil ‘memory’.

The process aims to produce a more uniform thickness across the width of the coil, whilst increased surface hardness and tensile strength provides the strength and durability required for many functional and decorative applications.

We offer a range of Surface Hardness and Tensile Strength to suit customer’s needs, so please specify your requirements.

The ’temper’ grade (e.g. 1/4 hard, 1/2 hard, 3/4 hard, full hard), or specified Tensile/Hardness gives a range to choose from depending on how much strength is needed.

We supply custom widths, thicknesses, and finishes along with dressed edges to suit your exact specifications and Stainless Steel Temper Rolled coils deliver premium quality and consistency for every project.

Contact our team for a quote to supply the best solution for your Temper Rolled Stainless Steel needs.